smj

Forum Guide

Traditional Council

Traditional Council

Posts: 1,819

|

Post by smj on Mar 24, 2007 22:00:08 GMT -5

easternhunter - I like the attitude! I'll bet this bow is going to rock, and you will be blown out of the water by what you end up with. I have seen jatoba used in glass lam bows before, just don't know of the whole bow being made of it before. I found some Brazilian red wood (I think it was...) today right next to the ipe in the decking section. I may go back and get me a board of that as well! Sure would make a pretty bow...

I look forward to seeing your next pics! Thanks for keeping us posted, and let me know if I can help in any way.

So who is next here in bow building 101?

|

|

|

|

Post by easternhunter on Mar 25, 2007 7:02:06 GMT -5

Thanks for the encouragement SMJ...did ya notice that we've seemed to hijack this thread from skipmaster?  "sorry about that chief" Well, maybe you could suggest a nice profile to use on this one....I was thinking about maybe 1.5" reflex closer to the tipsnothing else, although it's a struggle for me NOT to do another R/D profile. of course not as pronounced as the maple bow.LOL. I may run 1.5" full width halfway to midlimb then taper to tips. with dense wood like this, I bet I'll have to narrow the limbs to get it down to 50-55 lbs.... I know that Dryad bows has used Jatoba in the past, but never fully ran with it. Rudderbows offers it and actually speaks highly of it. It should at least be purty once finished, with unusual grain. not really eloaborate, but different from most I've seen. It comes with everything from yellowish cream to a nice reddish color (I'm using the reddish stuff) must be heartwood. Today, I'll clean up the riser block and trim out the hickory backing. I'll kepp ya posted. |

|

|

|

Post by BT on Mar 25, 2007 8:15:09 GMT -5

Sorry to hear about the bow eastern but as smj says .....worth the material cost in experience  |

|

|

|

Post by easternhunter on Mar 25, 2007 8:50:23 GMT -5

Mornin' BT...yup, I agree on that point.

At least I started with the attitude that I was experimenting and hoping to gain experience.

When it failed, I shrugged it off and started fresh.

Like someone said the other day...."if you ain't makin' shavings, you ain't makin' bows....something like that.LOL

|

|

smj

Forum Guide

Traditional Council

Traditional Council

Posts: 1,819

|

Post by smj on Mar 25, 2007 8:53:16 GMT -5

easternhunter - 1.5 inches of reflex will buy back most of the set you get once tillered and shot in. You could probably go a bit more than that amount without issue. So, for this bow, you will have the belly stock of jatoba, then a quarter inch lam of jatoba, and then a hickory backing? That should hold the form well - make absolute certain that you like the flex you get out of the belly wood before you glue anything up! Put your main clamps in place, step back and look at that puppy first! If you don't like the flex that you see, modifiy things a bit until you are pleased with the resulting curves. Then take it all down and do it again with glue.

If you do the R/D profile on this bow, don't try to glue the grip block on at the same time. Let the grip section curve to your form and then fit the grip block to the resulting curve of the bow. Seeing some of your work, I doubt you will have any troubles at all making the fit! For a reflex only bow, you could glue the grip block at the same time and will want to hold the limbs flat through the grip - with reflex being confined to the limb. Don't make the grip block to long, and again, look at the reflex that appears in your limbs before glue up. Make sure you like how the limbs curve. For example - you don't want all your reflex right at the grips. Probably want it out through the limb with a touch more in the last 1/3 of the limb. I am sure you have an idea in mind, just make sure you get it the way you want on the bow! Take a pic or two of the form pre glueup and we can talk about it a bit if you like.

|

|

|

|

Post by easternhunter on Mar 25, 2007 9:04:32 GMT -5

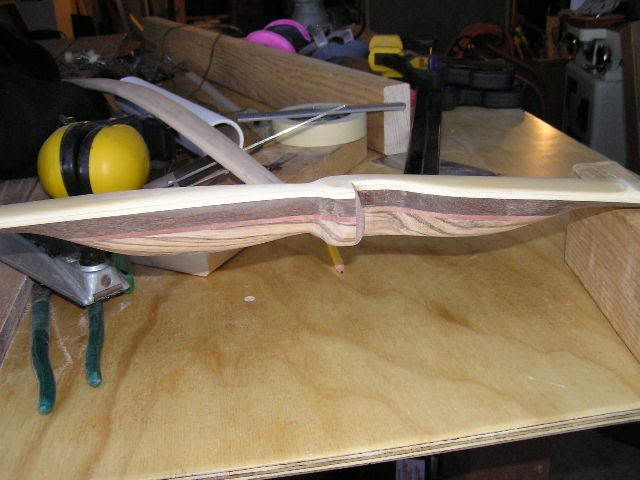

SMJ....You are correct in my lay-up of woods. What do you think about 1/8th inch thick hickory(may a hair less) Not enough? I could double that since I have 2 slats of that thickness. Or rip out a new slat 3/16" thick for this one? Riser block right now is just about 9" long...I'm was thinking of tapering the toes like a hill style grip, but now I'm wondering if I should do a nice rounded bulbous style grip like Dryad's? thoughts??? Any suggestions about limb width as I planned or go narrower? at fades likely will fine tune out at 1.25" wide..Really appreciate the help, and I hope all this inspires other newbies to get out there and try it...very therapeutic. ok...A COUPLE OF PICS OF RISER AND POWERLAM AFTER CLEAN-UP.     LAT PIC KINDA WAS TO SEE HOW THE BLOCK LOOKED WITH THE BELLY WOOD. |

|

smj

Forum Guide

Traditional Council

Traditional Council

Posts: 1,819

|

Post by smj on Mar 25, 2007 21:13:55 GMT -5

I think I'd go with the 3/16 inch hickory backing. Sorry... I don't have experience with a thinner backing lam. A pal of mine built a bow with a thinner lam - it broke. Not sure why, I didn't get to look it over close. Still, it is a data point.

So far as grip, I think you need to pick one and just do it. If you end up not liking it, change over to the other style for your next bow!

So far as width goes, I would not go under 1.25, and flirt with keeping a bit more width. The more narrow you go, the less area you have to distribute internal limb stress. At some point, and depending on the wood, narrow limbs become an issue. By backing the bow, you get away from a lot of those unbacked problems, but a little extra width won't hurt! Go to narrow and the stress can cause those little "wood wrinkles" to show up...

|

|

|

|

Post by easternhunter on Mar 25, 2007 22:27:48 GMT -5

All good advise there SMJ....I appreciate the help.

I will carry as much width as I can out to about mid'limb.....I can always take more off, but can't go back right?

OK...when I get a dry run ready, I'll get a couple of pics to show.

|

|

smj

Forum Guide

Traditional Council

Traditional Council

Posts: 1,819

|

Post by smj on Mar 26, 2007 21:10:25 GMT -5

So, I keep poking along on my bows... The ipe bow is just about ready to put a finish on it. A little more sanding to do... What does not show well is how much more smooth the surfaces are and how much better the flow of the grip section... Give me two or three good dry evenings and I'll have this bow done! I ran a wet cloth over the bow to raise the grain, not the bamboo, and will run over it once more with 400 grit sandpaper if I have some... Need to check I guess! HIt the nocks to finish getting those in shape, and smooth up the shelf in deep where due to the angles of the wood it is hard to get at with a palm sander. Here is the heel of the grip -  And here is the shelf side of the grip -  The other bow, I added a bit of stock to the grip to fill it out a bit -  I also found a very small knott, and will narrow the limb a bit prior to going on with the tillering. I didn't see it when the wood was untouched, it sure sanded out on the edge of the limb though... Another reason to keep a bit more limb width early on! By the way, if this was mid limb, I'd never even worry about it. Since it is on the edge of the limb, I'll take it out.  |

|

|

|

Post by easternhunter on Mar 27, 2007 10:09:05 GMT -5

How thick is that boo SMJ? Looks kinda thick along the edges. Question.....Since I got 2 3/32" slats of hickory, is it OK to laminate BOTH over my Jatoba? and what about the 4 to 1 ratio? Since my jatoba is 1/2" at the fades, wouldn't 1/8" be correct, or is a bit more hickory not a problem?  |

|