Post by 2chucks2 on Jan 9, 2008 22:11:19 GMT -5

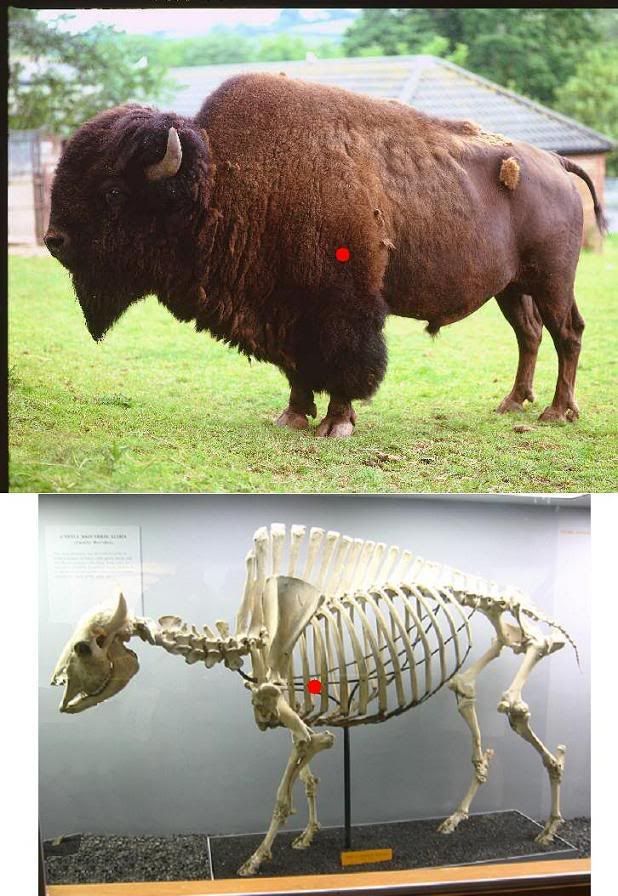

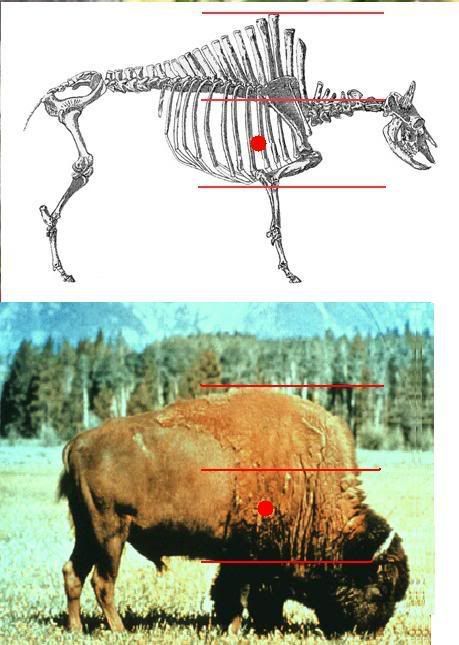

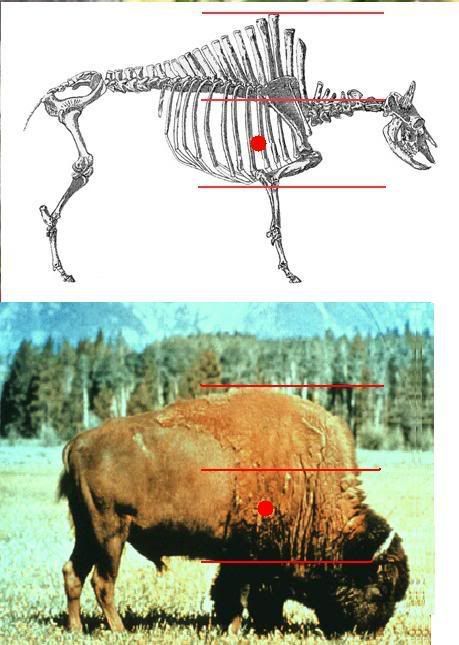

I’ve been asked by a friend (the guy who shot the deer with the broadhead in the brain) To outfit him with a arrow and broadhead combination for a February Buffalo hunt out West. He is using his current whitetail bow but wants more than the 350 grain arrow/broadhead set up he uses for deer. I agree with that. Everything I have heard and read about Bison is that you should be shooting for the heavy carpet that covers the front shoulders. I would expect that this hair is thick and matted and since the hunt will take place in February, that it might also be ice covered. For this reason, I will be shooting for an arrow weight over 700 grains.

After looking around for arow shafts, I settled on Carbon Express Heritage with the wood grain look. These shafts weigh around 12 grains per inch. The shafts are on order. Next, I picked the Wensel Woodsman as the broadhead for this hunt because I wanted him to use a strong, cut on contact head. The 3:1 aspect ratio of the woodsman means greater penetration. I ordered from 3Rivers, a half dozen 125 grain Woodsmans and since he will be screwing these into a carbon shaft, I also got some 100 grain steel adapters that are needed to mount a glue on style head to a carbon arrow. For added weight, I also got 50 grain brass arrow inserts instead of the normal 15 grain aluminum inserts. I also got him some brass weight washers.

I am trying to create a front heavy arrow (FOC moved forward) after reading Dr. Ashby’s report on extreme FOC arrows and their increased ability to penetrate. So far, that adds up to 285 grains at the tip alone. The shafting weighs 12 grains per inch and he uses a 29 inch shaft for 348 grains of carbon. He is using a luma nock and (3) 5 inch barred turkey feathers so that should add another 30 grains putting us at 663 grains so far.

Since my son and I are working on a broadhead collection, I used one of the Wensel Woodsmen to do a little testing. The woodsman has a very sharp tip but bison bones are big so I filed a secondary tip angle which shortened the head by about an 1/8 of an inch but will make the tip less likely to bend or curl upon impact with a large bone. I am planning on a worst case scenario in that he hits a rib on both sides of the bison.

Next, I took the woodsman and sharpened it to a fine edge and then lapped it on ceramic plates to get a mirror finish on the cutting edge.

In an effort to show my friend the benefits of a cut on contact head, I set up an experiment where he and I used two very common and popular heads on the market. A Muzzy and a Thunderhead that were in my collection. I used a short length of shaft and some sponges to keep the arrow from sliding around on the scale.

I used a very thick and heavy piece of boot leather as the test medium. I placed the leather over each broadhead and by holding the leather out at the edges, pressed down until the head passed thru the leather. My friend watched the scale to check the poundage. I started with the Muzzy. I pushed down until I reached 30 pounds of force and I could not get the tip to go thru the leather.

Next, I used the Thunderhead and when I applied 24 pounds of force, the head came thru but ripped the leather until the blades could start cutting. The thunder head hole is to the right on the picture above.

Lastly, we used the Woodsman and It went thru the leather so fast and with such ease that we repeated the test several times to make sure we could trust the results. After 4 tries, we kept coming up with the same results. It took 6 pounds of force to slice thru the leather and there was no tearing, just clean cuts. There are other heads on the market with cut on contact tips that are just as good but I think the Woodsman was a good choice for this hunt.

I hope to have the shafts in a few days so I can begin to construct the arrows. In order to reach the 700 plus final weight, I have decided to use a few 27 inch lengths of .065 string trimmer (weed whacker) line that will be placed inside the arrows. This will ad length from front to back but will not change the arrow spine which is 350. I will post more as the project progresses.

After looking around for arow shafts, I settled on Carbon Express Heritage with the wood grain look. These shafts weigh around 12 grains per inch. The shafts are on order. Next, I picked the Wensel Woodsman as the broadhead for this hunt because I wanted him to use a strong, cut on contact head. The 3:1 aspect ratio of the woodsman means greater penetration. I ordered from 3Rivers, a half dozen 125 grain Woodsmans and since he will be screwing these into a carbon shaft, I also got some 100 grain steel adapters that are needed to mount a glue on style head to a carbon arrow. For added weight, I also got 50 grain brass arrow inserts instead of the normal 15 grain aluminum inserts. I also got him some brass weight washers.

I am trying to create a front heavy arrow (FOC moved forward) after reading Dr. Ashby’s report on extreme FOC arrows and their increased ability to penetrate. So far, that adds up to 285 grains at the tip alone. The shafting weighs 12 grains per inch and he uses a 29 inch shaft for 348 grains of carbon. He is using a luma nock and (3) 5 inch barred turkey feathers so that should add another 30 grains putting us at 663 grains so far.

Since my son and I are working on a broadhead collection, I used one of the Wensel Woodsmen to do a little testing. The woodsman has a very sharp tip but bison bones are big so I filed a secondary tip angle which shortened the head by about an 1/8 of an inch but will make the tip less likely to bend or curl upon impact with a large bone. I am planning on a worst case scenario in that he hits a rib on both sides of the bison.

Next, I took the woodsman and sharpened it to a fine edge and then lapped it on ceramic plates to get a mirror finish on the cutting edge.

In an effort to show my friend the benefits of a cut on contact head, I set up an experiment where he and I used two very common and popular heads on the market. A Muzzy and a Thunderhead that were in my collection. I used a short length of shaft and some sponges to keep the arrow from sliding around on the scale.

I used a very thick and heavy piece of boot leather as the test medium. I placed the leather over each broadhead and by holding the leather out at the edges, pressed down until the head passed thru the leather. My friend watched the scale to check the poundage. I started with the Muzzy. I pushed down until I reached 30 pounds of force and I could not get the tip to go thru the leather.

Next, I used the Thunderhead and when I applied 24 pounds of force, the head came thru but ripped the leather until the blades could start cutting. The thunder head hole is to the right on the picture above.

Lastly, we used the Woodsman and It went thru the leather so fast and with such ease that we repeated the test several times to make sure we could trust the results. After 4 tries, we kept coming up with the same results. It took 6 pounds of force to slice thru the leather and there was no tearing, just clean cuts. There are other heads on the market with cut on contact tips that are just as good but I think the Woodsman was a good choice for this hunt.

I hope to have the shafts in a few days so I can begin to construct the arrows. In order to reach the 700 plus final weight, I have decided to use a few 27 inch lengths of .065 string trimmer (weed whacker) line that will be placed inside the arrows. This will ad length from front to back but will not change the arrow spine which is 350. I will post more as the project progresses.